“Because the foot is the foundation of the human body, and without women, humanity is nothing, the years have not dulled my passion for shoes.”

JOSEPH NAKAM

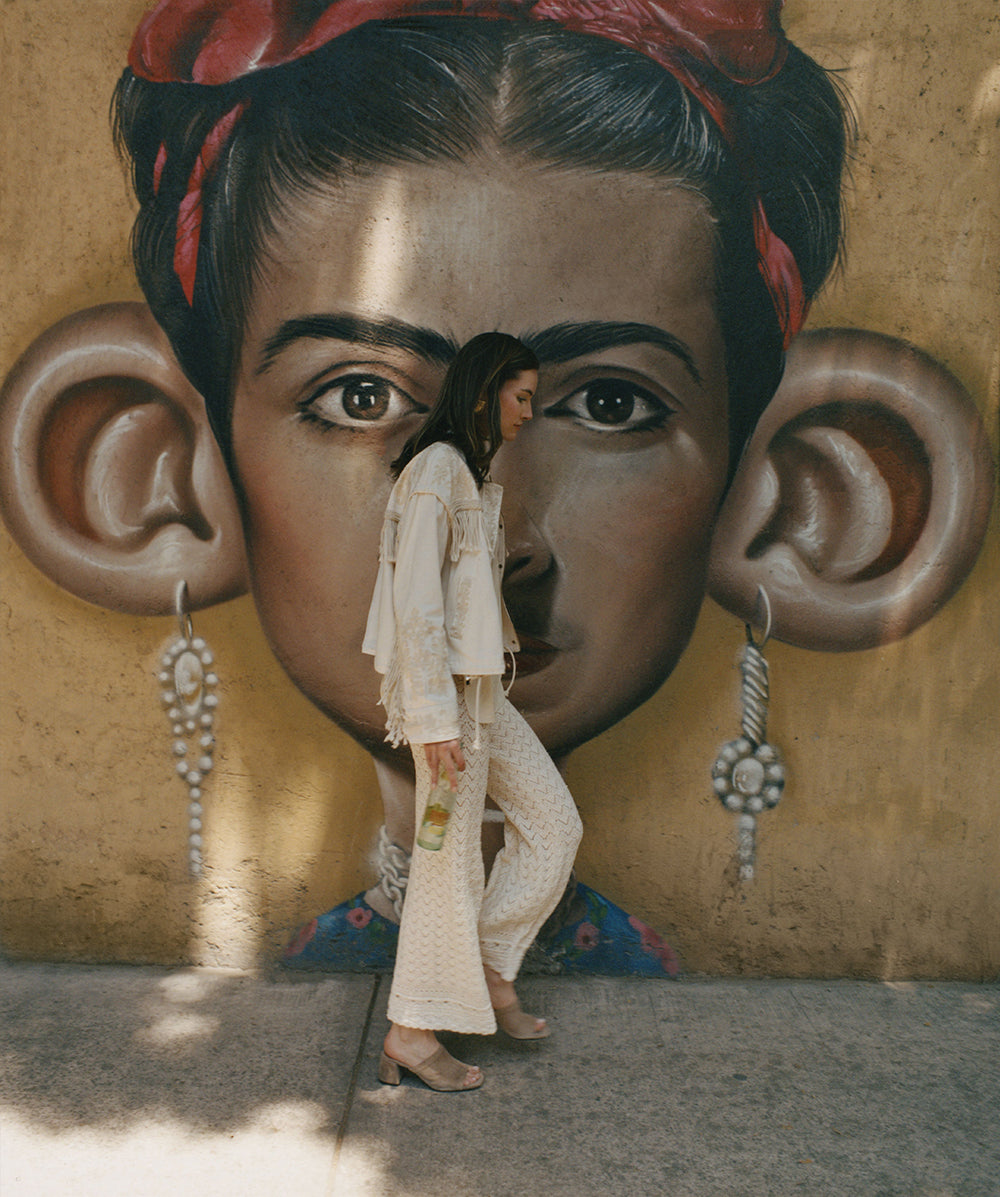

Excellence in materials, mastery of craftsmanship, and precision in technique are the key elements in creating Jonak's pieces. By combining precise production and accurate propositions, we continuously present a reinvented collection at the right price throughout the year.

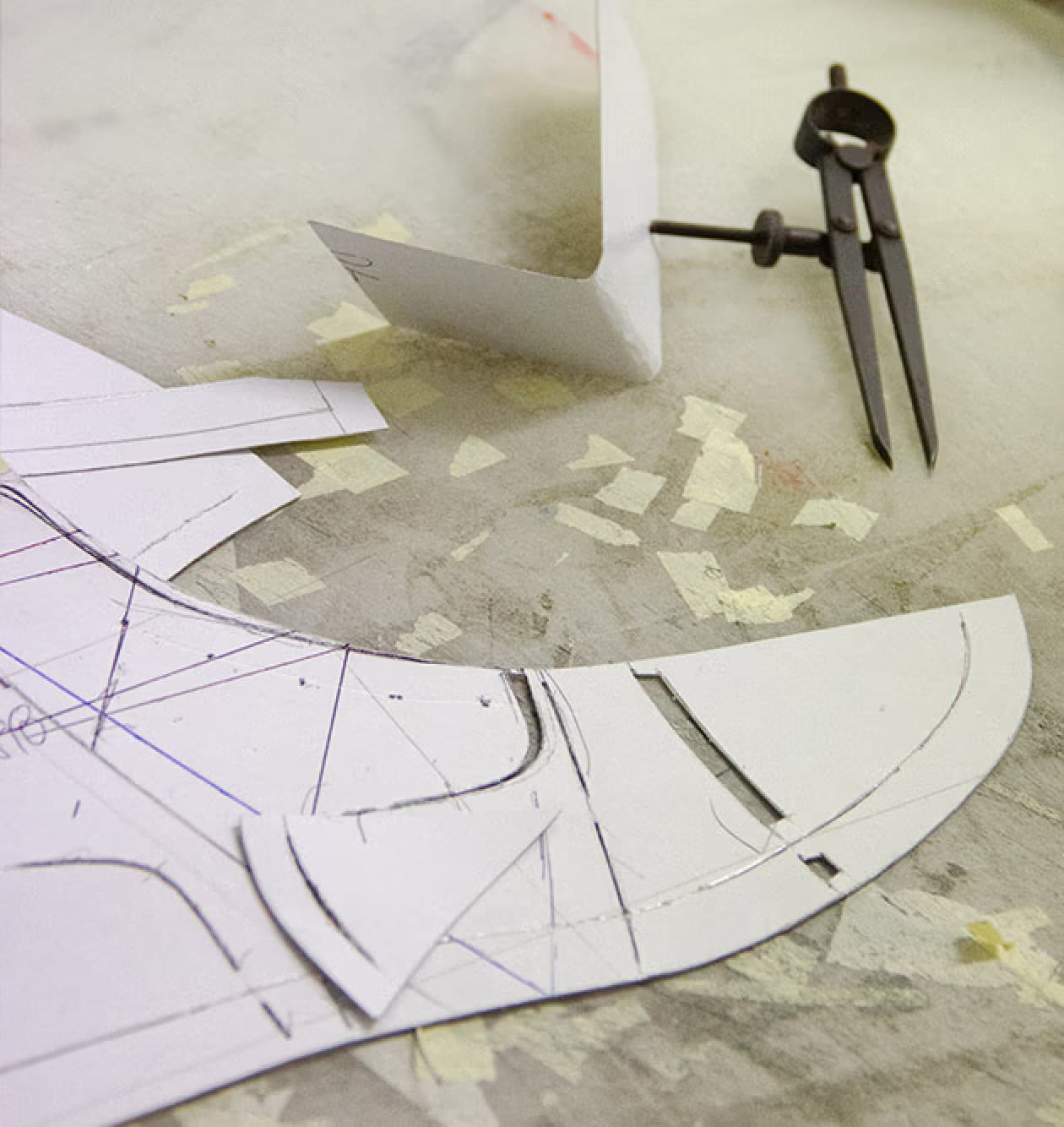

SKETCHING

After drawing inspiration from emerging trends, runway shows, as well as art, architecture, and everyday life, the design team gradually brings the models to life through sketches representing the forms to be developed.

LASTING

The base of the shoe, the three-dimensional last, is crafted based on the drawings and specifications. The last maker not only considers the stylistic aspect but also works on shaping the shoe for maximum comfort. It serves as a mold for the model.

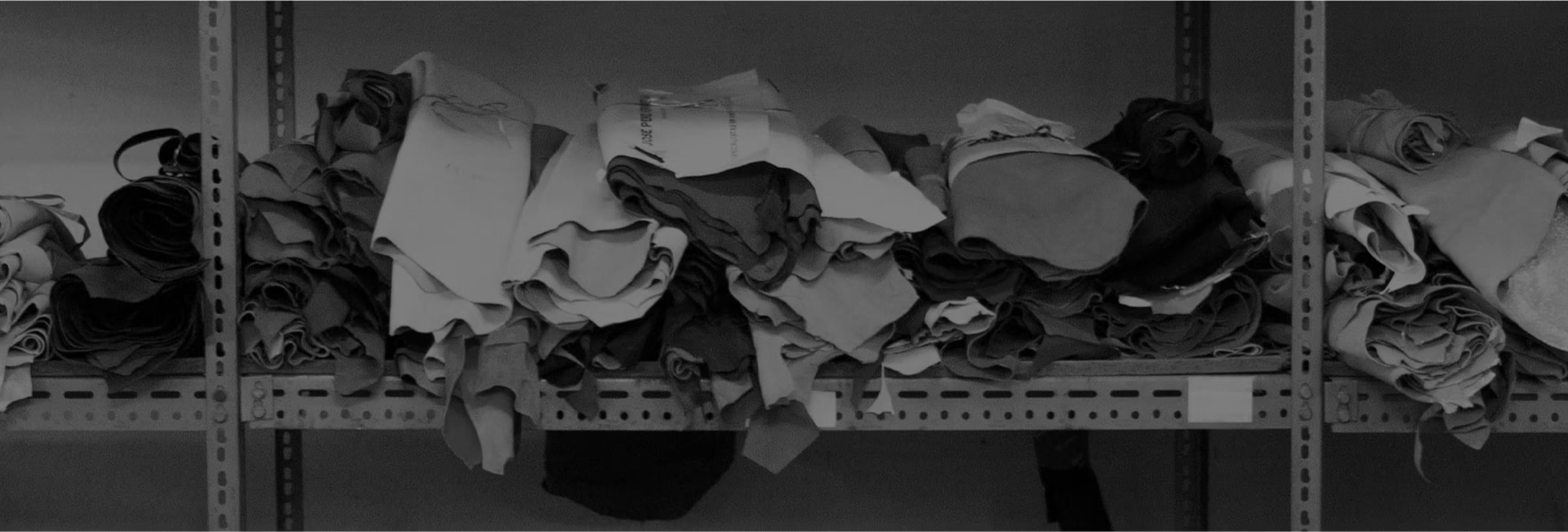

CUTTING

Using the pattern, the different pieces of the shoe are cut from the leather. Cutting can be done with a laser, die-cut, or by hand. The goal is to optimize the available surface area relative to the shapes to be cut to minimize waste.

STITCHING

Once cut, the elements are prepared to be assembled and form the upper part of the shoe. The leather pieces are stitched together. To avoid excess thickness at the connections, the stitcher trims them, intentionally reducing the thickness.

FOLDING AND SOCKLINING

The edges of the pieces are folded onto themselves, then glued and sewn for a more aesthetic finish. This is called folding, followed by socklining, where the front and back of the shoe are assembled.

LASTING

This is the stage where the shoe truly takes shape. The upper part is placed back on the last, and the materials are manipulated to conform to the volumes. Then, the upper is attached to the sole in several steps, depending on the model and its specificities.

FINISHING

Finally, the workshop pays attention to the important small details: attaching the insole, adding laces, eyelets, etc. The shoe is then cleaned, inspected, and packaged in its box.

SKETCHING

After drawing inspiration from emerging trends, runway shows, as well as art, architecture, and everyday life, the design team gradually brings the models to life through sketches representing the forms to be developed.

LASTING

The base of the shoe, the three-dimensional last, is crafted based on the drawings and specifications. The last maker not only considers the stylistic aspect but also works on shaping the shoe for maximum comfort. It serves as a mold for the model.

CUTTING

Using the pattern, the different pieces of the shoe are cut from the leather. Cutting can be done with a laser, die-cut, or by hand. The goal is to optimize the available surface area relative to the shapes to be cut to minimize waste.

STITCHING

Once cut, the elements are prepared to be assembled and form the upper part of the shoe. The leather pieces are stitched together. To avoid excess thickness at the connections, the stitcher trims them, intentionally reducing the thickness.

FOLDING AND SOCKLINING

The edges of the pieces are folded onto themselves, then glued and sewn for a more aesthetic finish. This is called folding, followed by socklining, where the front and back of the shoe are assembled.

LASTING

This is the stage where the shoe truly takes shape. The upper part is placed back on the last, and the materials are manipulated to conform to the volumes. Then, the upper is attached to the sole in several steps, depending on the model and its specificities.

FINISHING

Finally, the workshop pays attention to the important small details: attaching the insole, adding laces, eyelets, etc. The shoe is then cleaned, inspected, and packaged in its box.

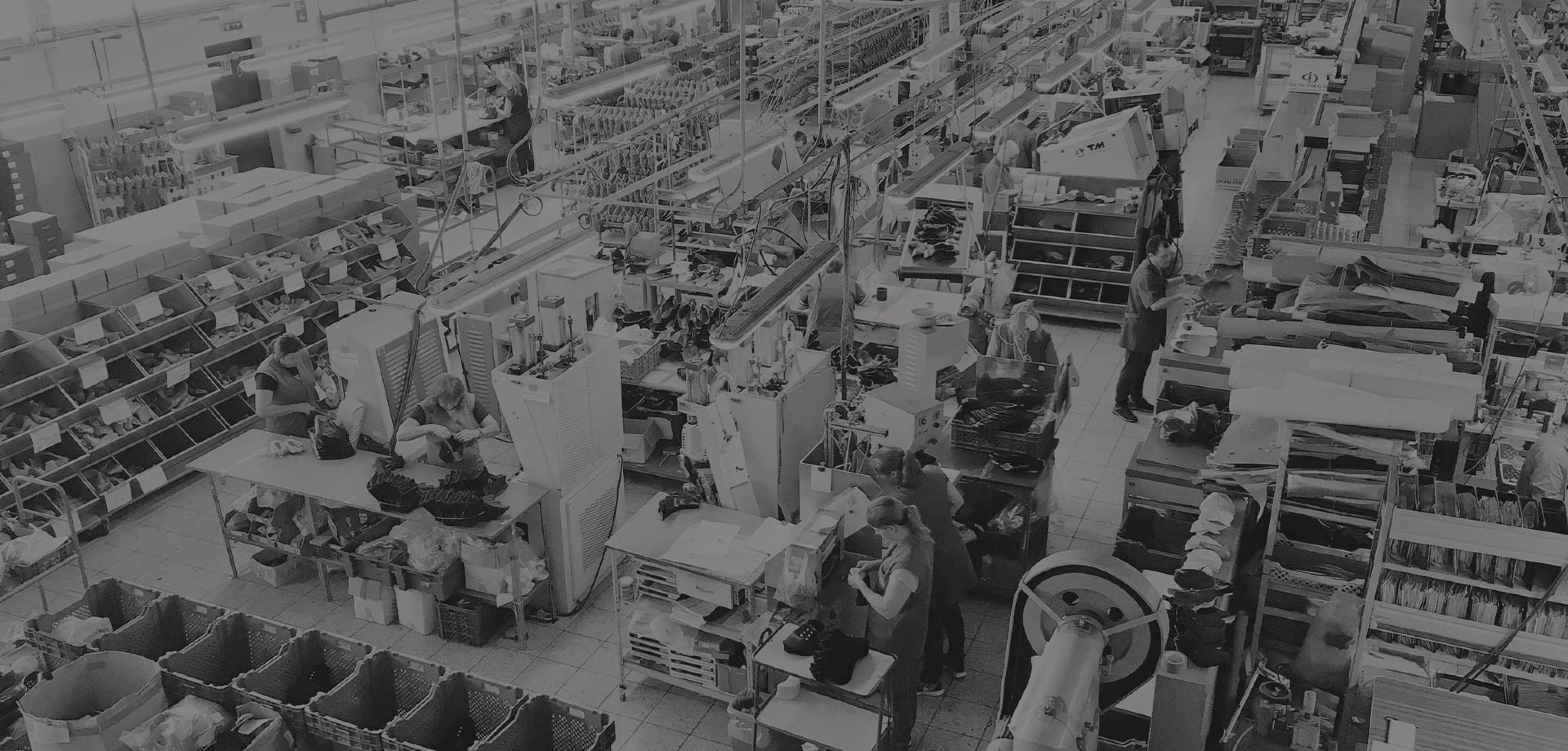

MADE IN PORTUGAL

In the northern region of Portugal, in the small town of Saint-Jean-de-Madère, some of Jonak's manufacturing workshops are located. This region is internationally renowned for its expertise in shoe-making. These workshops, along with their artisans, dedicate their skills to crafting Jonak's collections, handling cutting, assembly, stitching, lasting, and finishing. The entire production process is meticulously done by hand, following the traditions of shoemaking.